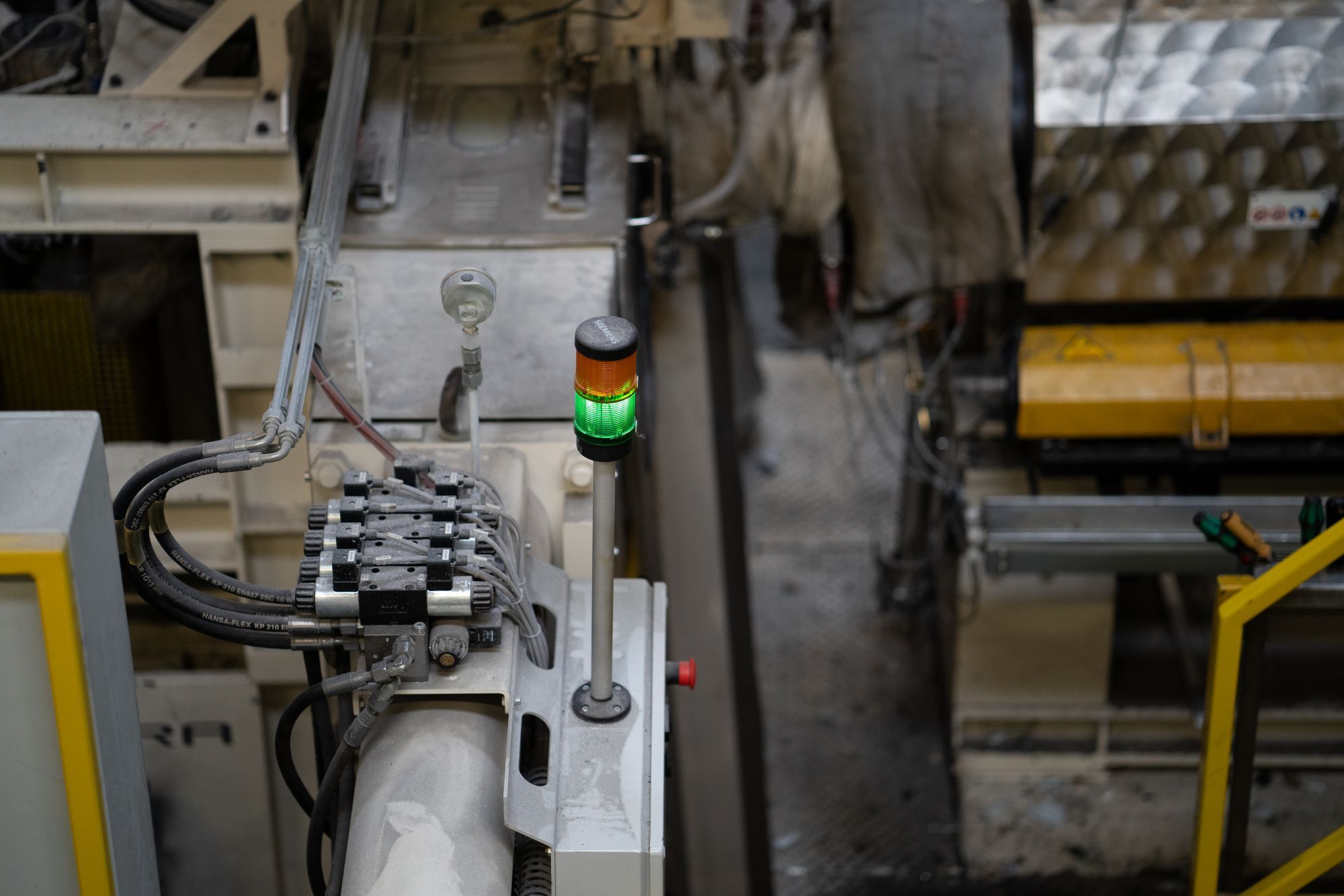

Temperature controllers - indicator & alarm units

Indicator and Alarm Units.

Measurement, Indication and Alarms.

Available in four standard DIN formats and complementing our range of world class PID controllers the Eurotherm range of indicators and alarm units provide accurate temperature or process measurement, clear indication with alphanumeric messaging and versatile alarming strategies

Contact us for more info

The Eurotherm piccolo™ P304i Melt Pressure indicator and P304c controller offer versatile solutions with advanced features and a wide range of hardware options that make them ideal for all types of plastic processing.

Both the piccolo™ P304i Melt Pressure indicator and P304c controller have a 50ms sample rate to give the fast-acting control and alarm functionality required in the plastics industry. The P304c controller provides outstanding control performance in an affordable package for a wide variety of pressure sensors.

Input/output flexibility

3204i, 32h8i, 3216i – Accurate indication of temperature and process measurements

The Eurotherm range of 3200i indicators offer accurate indication of temperature and process measurements. Process interlocks, including overtemperature furnace limits, are implemented using relay output channels.

The emphasis is on ease of use. A simple ‘Quick Start’ code is used to configure all the functions essential for indication and protecting your process.

The 2408i provides you with accurate indication and alarming of temperature and process measurements. Process interlocks, including over temperature furnace limits, are implemented using relay outputs.

- Large 5 digit display providing excellent visibility

- Furnace over temperature limits

- Extrusion melt pressure indication and alarming

- Fieldbus communications providing system integration

- Second process input provide additional alarming strategies

- Modular construction offering increased I/O flexibility